- Standardized demagnetizing tunnels in a continuous process

- The components to be demagnetized are conveyed through a coil opening and demagnetized as a result of the increased distance.

- The demagnetizing coils are fed directly from the mains supply (at 100% switch-on duration).

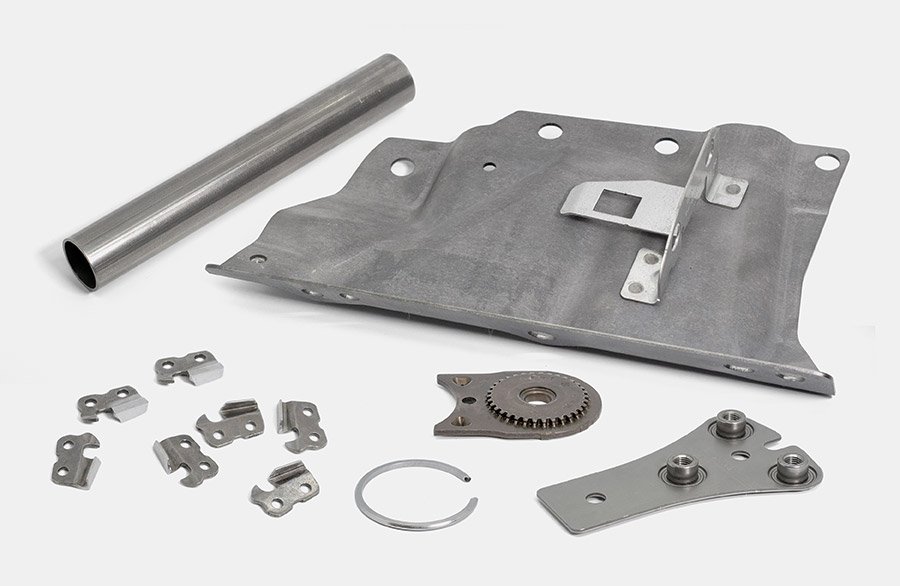

- For easy to demagnetize materials for a range of thin-walled and small parts

Reliable and robust

For easy to demagnetize loose parts

The CT series tunnel demagnetizers are robust devices based on tried and tested technology. The magnetic parts are continuously fed through the active opening of the coil and are demagnetized while being fed out along the coil axis.

Tried and tested tunnel coil program with standard effective openings of up to 750 x 550 mm. Quick and simple solutions for easy to demagnetize components.

Systems by Maurer Magnetic comply with the current common standards and are CE-compliant. Our company offers you only the highest quality products, designed to be extremely robust and sustainable.

Technical data*

| Coil module | CT1 | CT2 | CT3 | CT4 | CT5 | CT6 | CT7 | CT8 | |

| External dimensions¹ | W | 451 | 561 | 556 | 697 | 706 | 671 | 849 | 1046 |

| mm | H | 282 | 315 | 435 | 385 | 535 | 555 | 735 | 735 |

| D | 170 | 185 | 200 | 250 | 250 | 250 | 367 | 360 | |

| Active opening | W | 150 | 260 | 250 | 400 | 400 | 400 | 550 | 750 |

| mm | H | 100 | 130 | 250 | 200 | 350 | 400 | 550 | 550 |

| D | 120 | 135 | 150 | 200 | 200 | 220 | 337 | 330 | |

| Weight | kg | 41 | 62 | 84 | 110 | 120 | 130 | 190 | 230 |

| Degree of protection IP | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Maximum field strength² | kA/m | 25 | 29 | 20 | 26 | 18 | 17 | 11 | 9 |

| Outlet section³ | mm | 500 | 780 | 1000 | 1200 | 1500 | 1600 | 2200 | 2600 |

| Duty cycle | S1, 100% | ||||||||

| Power supply | VAC | 1NPE 200 – 240 | 2PE 400 – 480 | ||||||

| HZ | 50 / 604 | ||||||||

| Device protection | A | 6.3 | 14 | 18 | 23 | 32 | 32 | 32 | 32 |

Coil module

1 Approximations

2 Effective value lower by a factor of 1.41

3 Minimum distance for removing the part along the coil axis

4 The maximum field strength is reduced at 60 Hz

* All informations are without guarantee