Maurer Degaussing® Demagnetizing machines work with pulse demagnetization.

The component to be demagnetized is placed in the demagnetizing device, usually a coil, and supplied with energy by means of power electronics. The workpiece is demagnetized by an alternating monotonically decreasing magnetic alternating field. The very high magnetic field strength, the precision of the decreasing alternating field and the parameterizable demagnetizing frequency – these are the special performance features of Maurer-Degaussing demagnetizing technology. Thanks to them, results of the highest quality are achieved. Conventional demagnetizing systems mostly use apparent power which is ineffective.

Maurer Degaussing® machines compensate for this and convert most of the energy into effective power, thus achieving a very high degree of efficiency. Process-relevant parameters, such as field strength, frequency or cycle time, are designed by means of preliminary tests and the demagnetizing machines are designed, optimized and parameterized accordingly.a single setting can handle a whole range of different parts. This results in a very high process capability.

Customers thus receive a demagnetizing solution that fully meets their individual requirements.

The following points distinguish the services of Maurer Magnetic:

- The demagnetizing process of the machines needs in most cases only one setting

The machines are operated manually at the push of a button or automatically via the standard integrated interface. - process-safe compliance with residual magnetism limits through integrated monitoring of the demagnetizing pulse

- Demagnetizing machines are available for rent if required. All standard devices are available for rent.

- Maurer Magnetic offers degaussing as a service. With mobile demagnetizing machines of various types, our specially trained engineers can handle a wide range of demagnetizing tasks.

- Customer enquiries are always handled directly by specialised engineers, Maurer Magnetic has over 90 years of experience in magnet technology.

- Every problem is analysed in detail, the preparation of offers is based on documented test results, successfully used machines and verified calculations.

- Compared to competitors, Maurer-Degaussing coils generate much higher field strengths.

- The package of demagnetization frequency, magnetic field strength and shielding is matched to the component size, geometry and alloy for optimum results.

Customized machines

For high field performance, coil dimensions and field calculations must be optimized according to the intended use. The opening and field strength of the coil flows squarely into the required power.

High demands on demagnetizing quality, process capability, high productivity and optimally used energy requirements as well as extensive integration characterize this high-performance machine.

The little brother from the high performance segment. The performance class is in the medium performance range, is suitable for stand-alone operation and can be fully integrated.

Standard machines

If lower field outputs are required, standard coils cannot always be used with optimally matched opening sizes.

Specially designed to demagnetise residual magnetism in containers of cleaning systems. These products reduce the magnetic values on the components and create good conditions to efficiently clean ferromagnetic material in washing processes. However, the demagnetizing performance is limited. An integration package of the power section is available for integration into washing machines.

Machine parts in a somewhat more massive design are handled well with this combination.

Long stretched or endless long bars, tubes and also profiles are treated here in a continuous throughput magnetization. Increased cooling of the coil enables high demagnetising fields.

A powerful device is available here as an entry-level model. Thanks to its 230-volt connection, it is particularly suitable for laboratories, tool shops and service points.

Standard products

These are the classic demagnetizing devices with good demagnetizing properties, but with very limited application possibilities.

Mains-operated coils are suitable for soft magnetic, thin-walled steel parts which can be demagnetized with little magnetic field power in continuous operation.

Surface magnetism up to a depth of 10 mm is reliably removed. The device is intended for manual operation and is equipped with the AFDT demagnetization circuit to prevent unintentional magnetization when the device is switched off.

The hand-held device removes surface magnetism from large components up to a depth of 15 mm.

Options

Integration of degaussing machines and field compensation for bar degaussers

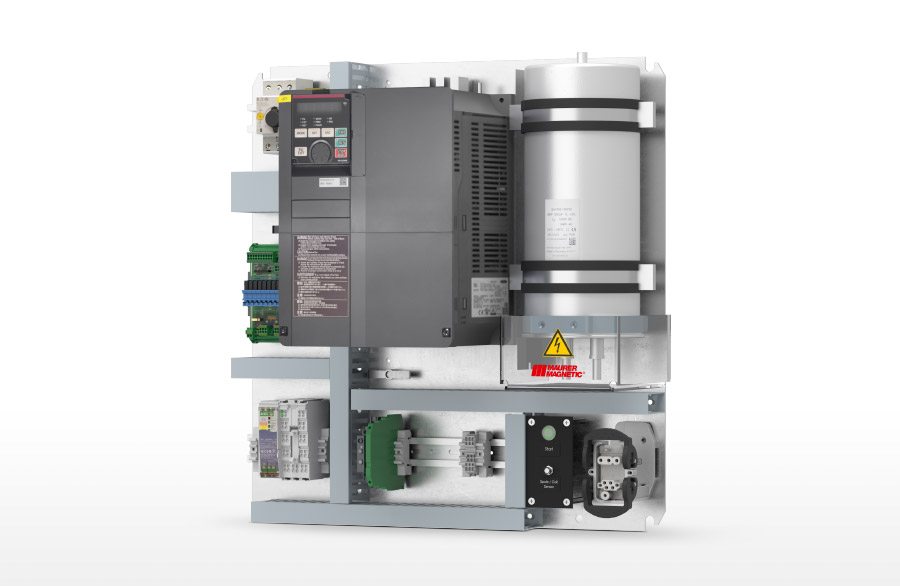

The power unit is supplied on a mounting plate for control cabinet installation in CE installation declaration. This option is reserved exclusively for system integrators.

This is an addition to our bar demagnetizer RE. It compensates induced environmental fields and neutralizes the demagnetization.