Maurer-Degaussing® can be used to remove residual magnetism on and in workpieces of various dimensions and shapes reliably

Examples are large parts with weights of several tonnes, hard metal, packaging with needles or cannulas, completely filled washing baskets, sintered parts, assemblies, containers with technical springs in bulk goods, parts in steel containers and much more.

Completely, safe and all-round demagnetisation for automated production processes and manual operation. Demagnetising with Maurer-Degaussing® is performed fully automatically and within a few seconds. Maurer-Degaussing® is state of the art demagnetisation from the demagnetisation technology leader. High productivity, robustness and the reproducibility of results are the main features.

Con rod, crankshaft, gear wheel, bushings, joints, shafts, sensors, particle adhesion, welding, coating

CN machine, press, turbine, adapter and sintering press, constructed assemblies, separation, material determination, eddy current testing, assembly cleanliness, fault-free operation of cutting dies, chrome-plating

Ball bearings, rolling bearings, avoiding magnetically induced bearing damage, adhering to residual magnetism limit values

Bridges, rails, armouring iron, steel beams, piping, airfields, building envelopes for sensitive instruments in research and medicine

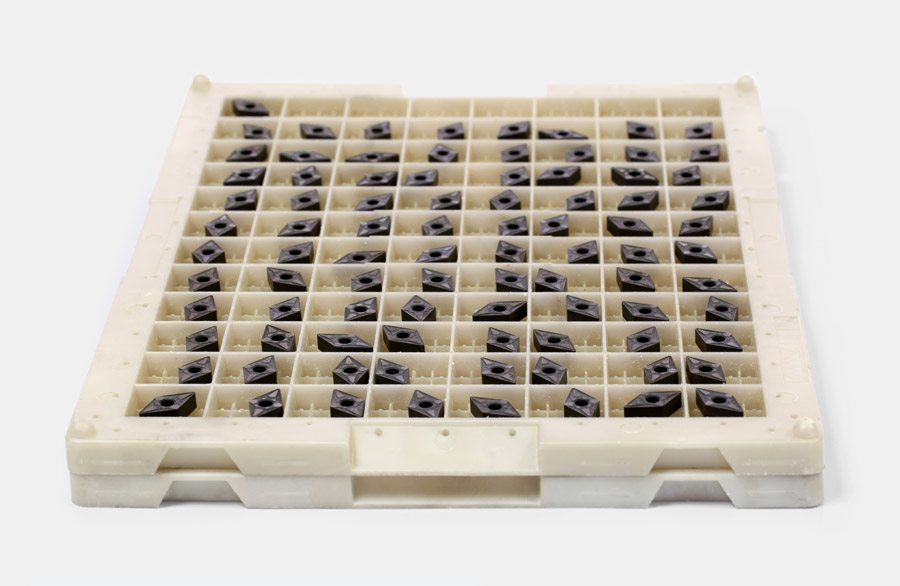

Hard metal tools, particle adhesion, coating problems, chip adhesion when using the tools

Springs of all shapes and sizes. Formed parts made mainly of stainless steel and high-alloyed steel, connectors such as screws, rivets, clamps