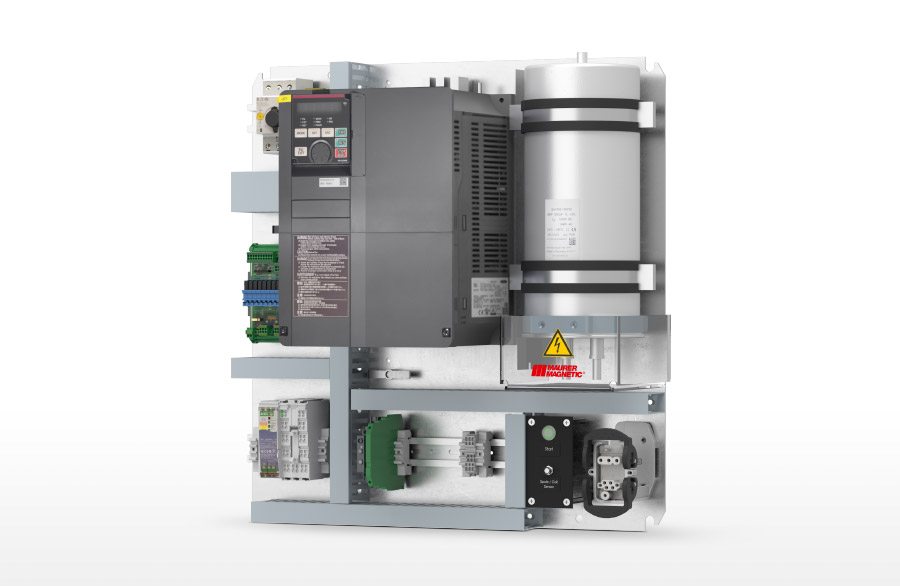

Power module designed for integration into switch cabinets for CT-U, SE, VE, RE and DS

- The DN integration allows an integrated operation of compatible coil modules with the patented Maurer Degaussing® pulse demagnetization

- Can be installed directly into the existing switch cabinet on the customer’s production machine

- The power module entirely built onto the mounting plate eliminates the need for any additional cabinet on the machine

- Fast and fault-free assembly and commissioning due to the ready-made mounting plate configured at the factory with plug connections on the output side

- Efficient and easy connection with standard integrated field bus coupler

- The module combines all advantages of the Maurer Degaussing® demagnetizing process with the SE/CT-U/VE/RE/DS coils

«Ready-made»

Completely configured and ready-made setup on the mounting plate

The DN Integration power module offers space-saving integration into switch cabinets, allowing a simpler system layout for cleaning systems, for example, without requiring an additional switch cabinet for demagnetization. With the standard integrated field bus coupler and the pre-tested and ready-to-use controller on the mounting plate, easy and trouble-free integration is guaranteed. The system status is displayed completely and clearly visible on the interface board with the aid of LEDS, and is then transferred and signaled to the coil modules. Consistent use of industrial standard components ensures a long-term, trouble-free operation.

In 2001, Maurer Magnetic developed the Maurer Degaussing® demagnetizing process, for which a patent was applied for. With our many years of experience and the expertise we have acquired over time, our technology has been continuously enhanced, while our new relevant patents supplement it. Our in-house production also allows us to implement customer demands quickly and unimpeded, while ensuring our quality standards at the same time.

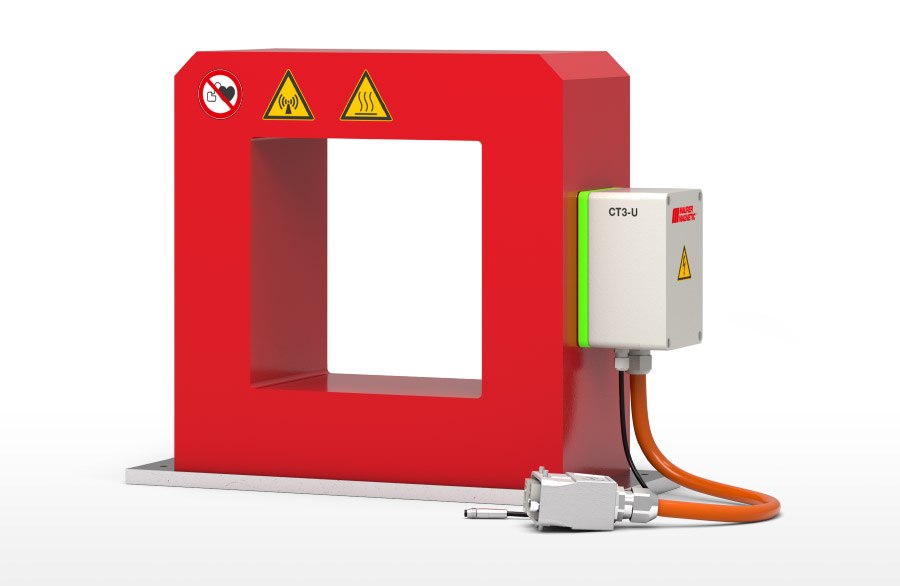

Compatible coil modules

| CT-U-coils | SE-coils | VE-High performance coils |

| For a variety of demanding Industrial applications | Optimized for productive and efficient demagnetization in the industrial component cleaning | High field strengths through individual design, for demanding demagnetization tasks at low residual magnetism limit values and deep demagnetization |

| RE-coils | DS-coils | |

| Optimized to efficiently demagnetize bars and tubes in the production line | Optimized for productive and efficient demagnetization of surfaces of hard-to-reach components such as railroad rails or large rolling bearings |

Technical data*

| Power module | DN-750-Int | DN-1100-Int | DN-1850-Int | |

| Dimensions mounting plate | W | 575 | 575 | 575 |

| (mm) | H | 570 | 570 | 570 |

| D | 310 | 310 | 310 | |

| Power supply | VAC | 3PE 380 – 480 | ||

| Hz | 50 / 60 | |||

| Control connection | V | 24 | ||

| Hz | DC | |||

| 1A fuse for control, 4A fuse for fan, 1A fuse for fieldbus coupler | ||||

| Weight | kg | 18 | 20 | 25 |

| Peak current1,2 | A | 36 | 52 | 80 |

| Internal fuse | A | 20 | 20 | 20 |

| Connection | Standard with fieldbus coupler via Profibus, Ethernet, Profinet, CANopen or other protocols (to be defined when ordering). Alternatively, digital inputs and outputs are available. | |||

Technical data

| Options |

|

1 Effective value lower by a factor of 1.41

2 In continuous operation it is 2 times lower

* All informations are without guarantee