- The maximum field strength combined with highly precise pulse control positions this series on the leading edge of the Maurer Degaussing® technology

- High-performance demagnetizing coils with field strengths exceeding 400 kA/m

- Power modules with up to 200 kW demagnetizing performance

- The demagnetizing solution is tailored optimally for each particular application with the aim of increased efficiency

- For demanding demagnetization tasks of hard-to-demagnetize components, for which process-reliable adherence to the limit values relating to residual magnetism is a must

- Productive demagnetization of large bulk materials or heavy individual parts using highly precise pulse control

- Customized process automation

- In traditional coils, electric current is converted into magnetic field strength with a very unfavorable reactive current ratio. The drawn energy is nearly fully converted into active power in the HLE series

Maurer Magnetic

Magnetically pure

In state-of-the-art industrial production processes, the standard requirements for magnetism limit values on ferromagnetic components are between 2 A/cm and 4 A/cm, such as for precision cleaning or electron beam welding, in which smooth processes cannot be reached without the lowest magnetism values.

It is essential for a trouble-free production chain that consideration is also given to magnetism. The very high field strengths of the HLE allow a complete demagnetization of components as process preparation, because they no longer re-magnetize themselves on their own.

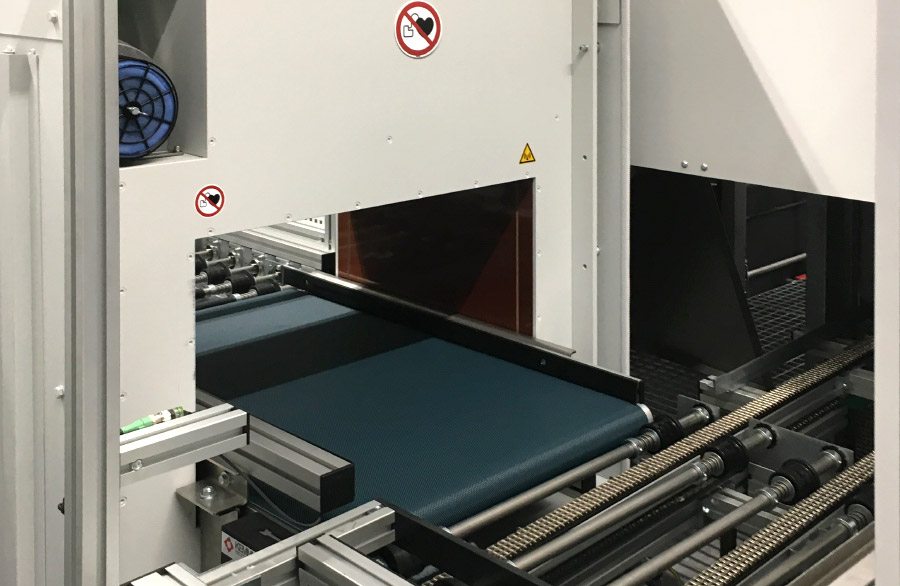

The HLE + DM high-performance demagnetizers represent leading edge demagnetizing systems: maximum demagnetizing performance coupled with high throughput. Demagnetize filled parts carriers, transport baskets or complex assemblies with a pulse lasting only a few seconds – and in a quality that up until now has been unrivaled.

With the powerful and brief demagnetizing pulse, the tailor-made coil opening and the field strength designed for each specific case separately, the energy requirement of the demagnetizing process is kept as low as possible.

In 2001, Maurer Magnetic developed the Maurer Degaussing® demagnetizing process, for which a patent was applied for. With our many years of experience and the expertise we have acquired over time, our technology has been continuously enhanced, while our new relevant patents supplement it. Our in-house production also allows us to implement customer demands quickly and unimpeded, while ensuring our quality standards at the same time.

Applications

Demagnetization with high-performance coils

The demagnetizer is designed specifically to be integrated into highly automated production processes in an industrial environment. The excellent demagnetizing performance makes this device the leading-edge demagnetizer in industrial environments.

The magnetic field, which depending on the need, can release a field strength exceeding 400 kA/m, nearly completely demagnetizes hard-magnetic materials, internal parts in assemblies or large bulk quantities in no time at all.

The HLE high-performance coil module is ideally sized to match the customer-specific application in terms of its performance and the dimensions of the active opening. The Maurer Degaussing® process and the effective air cooling provide for a high clock rate and productivity. The housing is made of a rugged, fully-insulating material.

Ideally tailor-made demagnetizing solution

The demagnetization parameters are determined in preliminary testing or based on experience from similar scenarios. The demagnetization solution is implemented promptly with optimally designed power and coil modules.

Range of parts

- The most demanding components with the highest demagnetization requirements

- Large, filled laundry baskets for improved cleanliness

- Tools, small parts in bulk

- Assemblies consisting of a variety of materials

- Built-in hard metal parts

Cutting-edge technology

For highest requirements

The DM high-performance modules consist of the power and control components needed to operate the fixed coil modules.

DM 86 – 450 Power Module

- Patented pulse demagnetizer, which guarantees that the material is demagnetized all the way into the core

- Can be easily connected into automated production lines thanks to 24 V I/O interface

- Interface for a trigger sensor for autonomous pulse triggering comes standard

- Operating status lights

- Intuitive, reliable operation

- Demagnetization in pulse mode

- Robust design suitable for industrial applications

- Reactive current compensated

Technical data*

| High-performance demagnetizer | HLE | |

| Customer-specific | W | max. 1730 |

| external dimensions | H | max. 1930 |

| (mm) | D | max. 1100 |

| Customer-specific | W | max. 1500 |

| active opening | H | max. 1500 |

| (mm) | D | max. 1000 |

| Weight | kg | Typically 80 to 800 |

| Degree of protection IP | 20 | |

| Maximum field strength1 | kA/m | Typically 100 to over 400, inversely proportional to the active opening |

| Cycle time | Typically 2 to 6 pulse / min | |

| Demagnetizing frequency | Designed customer-specific |

| Power module | DM86 | DM110 | DM140 | DM200 | DM450 | |

| External dimensions | W | 1000 | 1000 | 1000 | 1000 | 1200 |

| (mm) | H | 1400 | 1400 | 1400 | 1400 | 2200 |

| D | 400 | 400 | 400 | 400 | 400 | |

| Power supply | VAC | 3PE 380 – 480 | ||||

| Hz | 50 / 60 | |||||

| Weight | kg | 100 | 120 | 125 | 130 | 200 |

| Degree of protection IP | 53 | 53 | 53 | 53 | 53 | |

| Peak current1,2 | A | 121 | 155 | 197 | 282 | 635 |

| Internal fuse | A | 63 | 63 | 63 | 63 | 125 |

| Suitability for automation | Yes | Yes | Yes | Yes | Yes | |

High-performance demagnetizer

Power module

| Options |

|

1 Effective value lower by a factor of 1.41

2 In continuous operation it is 2 times lower

* All informations are without guarantee