- With an almost 4 – 16 times higher system performance as compared to mains-operated coils

- The standard coil program offers a cost-effective solution to a variety of applications

- Short cycle times due to factory-configured demagnetization pulse parameters, adapted to the range of parts

- For industrial applications for which the magnetic field strength of a conventional continuous coil is not sufficient

- Depending on the application, the demagnetizing coils are operated either in a pulse or in continuous process

- The patented CFT® keeps the magnetic field consistently high, irrespective of the coil’s degree of filling

Maurer Magnetic

Magnetically pure

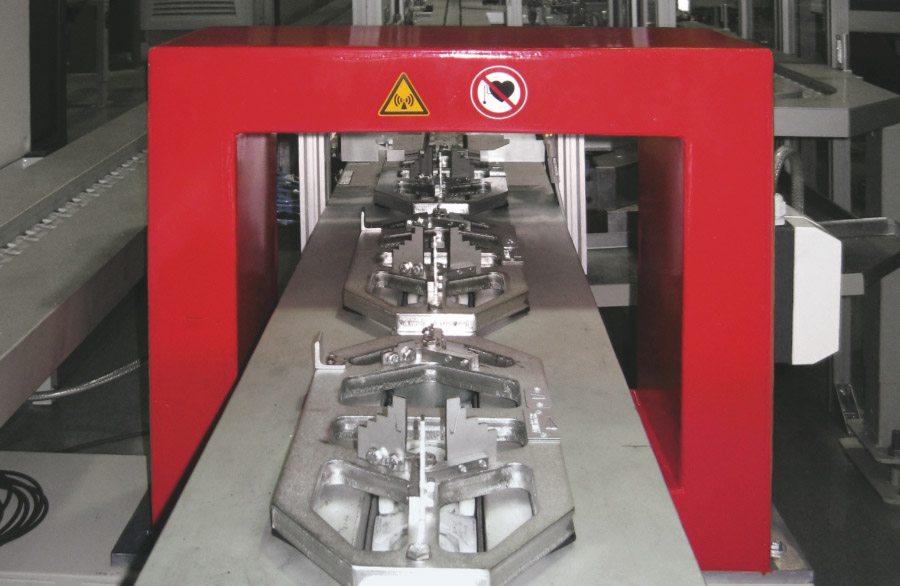

The classic tunnel demagnetizers have been in use more or less successfully in the industry for several decades. For the most part, their use and application options are fairly well known. Modern materials require increasingly higher demagnetizing field strengths in order remove any residual magnetism from them. Maurer Magnetic has brought the classic tunnel demagnetizers to a whole new level by adding the patented CFT® (Constant Field Technology). As compared to traditionally mains-operated coils, this increases the demagnetizing performance by a multiplier of 4 to 16. This opens up to entirely new possibilities: For example, heavier workpieces or several parts can be successfully demagnetized at the same time. Thanks to the control interfaces prepared in advance, integration into automated sequences is extremely easy.

This system can replace any demagnetizing coils already in use, which tend to show a decreased performance, and at the same place with the aim of meeting current and future requirements.

In 2001, Maurer Magnetic developed the Maurer Degaussing® demagnetizing process, for which a patent was applied for. With our many years of experience and the expertise we have acquired over time, our technology has been continuously enhanced, while our new relevant patents supplement it. Our in-house production also allows us to implement customer demands quickly and unimpeded, while ensuring our quality standards at the same time.

Applications

Can be used for versatile applications in automation

The magnetically enhanced demagnetizing coils are either used in continuous operation or in pulse mode, making them suitable for both consistent and inconsistent material flow.

Universal in manual mode

Components are placed in the coil and are generally demagnetized with a pulse; magnetically resilient parts can also be treated with several pulses and by sliding an elongated component. When used in an automated production line, the device is extremely space-saving, because it does not require a run-off area, such as a conveyor belt or a roller conveyor.

Coil Module CT-U

The CT-U coil module is completely cast with insulating material. The coils are fitted with temperature sensors to prevent overheating. The coil module is connected to the power module with a 3 m long power cable; upon customer request, it can be adjusted.

What demagnetizing with CT-U + DN means for you:

- Process-reliable demagnetizing

- Multiple parts treatment

- Energy-saving process

- Fast process

- Space-saving setup

- Process-reliable fulfillment of customer’s residual magnetism limits

Range of parts

- Larger parts with walls several centimeters in thickness

- Rods/ tubes/ profiles

- Bulk goods

- Individual and small parts

Cutting-edge technology

For best possible demagnetizing

This power module includes the power, interface and control elements of the demagnetizing system. The connection cables between the coil module and the power module are pluggable. By default, the power module is configured in pulse mode; continuous operation is also available as an option.

Power Module DN150 – 1850

- Patented pulse demagnetizer, guaranteeing highest possible material demagnetization

- Can be easily connected into automated production lines thanks to 24 V I/O interface

- Interface for a trigger sensor for autonomous pulse triggering comes standard

- Four power module types available

- Operating status lights

- Intuitive, reliable operation

- Demagnetization in pulse mode

- Robust design suitable for industrial applications

- Versatile system

The power module is also available for integration into existing switch cabinets. Please refer to the «DN-Integration» brochure for more information.

Technical data*

| Coil module | CT1-U | CT2-U | CT3-U | CT4-U | CT5-U | CT6-U | CT7-U | CT8-U | |

| External dimensions¹ | W | 456 | 566 | 561 | 702 | 711 | 676 | 854 | 1051 |

| mm | H | 282 | 315 | 435 | 385 | 535 | 555 | 735 | 735 |

| D | 170 | 185 | 200 | 250 | 250 | 250 | 367 | 360 | |

| Active opening | W | 150 | 260 | 250 | 400 | 400 | 400 | 550 | 750 |

| mm | H | 100 | 130 | 250 | 200 | 350 | 400 | 550 | 550 |

| D | 120 | 135 | 150 | 200 | 200 | 220 | 337 | 330 | |

| Weight | kg | 41 | 62 | 84 | 110 | 120 | 130 | 190 | 230 |

| Degree of protection IP | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | |

| Maximum field strength² | kA/m | 93 | 66 | 48 | 47 | 32 | 30 | 20 | 16 |

| Cycle time | 1 pulse / 10 s | ||||||||

| Demagnetizing frequency | Designed customer-specific | ||||||||

| Power module | DN150 | DN750 | DN1100 | DN1850 | |

| External dimensions | W | 300 | 600 | 600 | 600 |

| (mm) | H | 400 | 600 | 600 | 600 |

| D | 210 | 350 | 350 | 350 | |

| Power supply | VAC | 1NPE 200 – 240 | 3PE 380 – 480 | ||

| Hz | 50 / 60 | ||||

| Weight | kg | 12 | 45 | 45 | 50 |

| Degree of protection IP | 51 | 51 | 51 | 51 | |

| Peak current2 | A | 203 | 364 | 524 | 804 |

| Internal fuse | A | 10 | 20 | 20 | 20 |

| Suitability for automation | Yes | Yes | Yes | Yes | |

Coil module

Power module

| Options |

|

1 Approximations

2 Effective value lower by a factor of 1.41

3 In continuous operation it is 2 times lower

4 In continuous operation it is 1.5 times lower

* All informations are without guarantee